Heavy Equipment Inspection - Caterpillar Photo Inspections and Reports

ELGIN, TEXAS

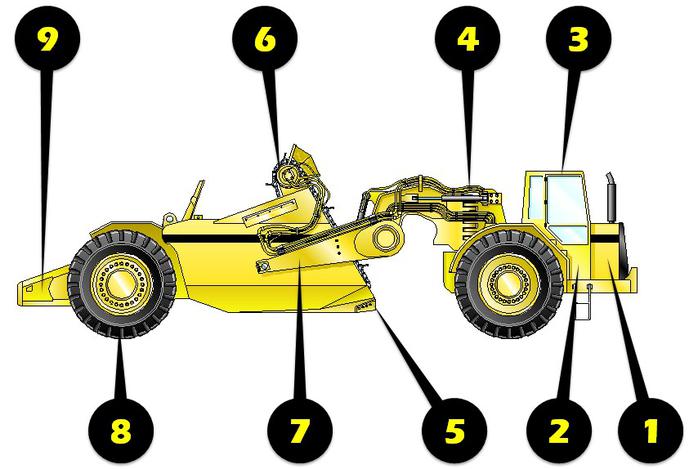

1. Engine: Inspect both engine fluid levels and note condition of each type of fluid. Note any visible oil or coolant leaks. Examine exhaust systems and air intake system for leaks and damage. Check condition of radiator and front grille; examine bumper and ripper for damage.

2. Battery: Inspect battery compartment for corrosion and rust. Make sure batteries are in good condition and the right size are properly fitted. Check any sight glasses or dipsticks in this area. Make sure fuel tank and hydraulic fluid tank are in good condition and leak free.

3. Cab: Examine cab interior for overall condition, including all switches, controls, and seat. Make sure all safety systems are present and working. Cab and instrument glass should be unbroken. Confirm all gauge functionality and activity. No drill holes or integrity issues should be seen in ROPS. While in cab, engage pan in ground and watch linkage for extra play.

4. Articulation: Inspect gooseneck and articulation joints for excessive wear, damage, and play. All hydraulic cylinders should appear dry and in good condition with no pitting, discoloration, and no extra play in their range of motion. Examine all visible rod sections for damage. Make sure all hydraulic lines and connections are in good condition, with no leaks or seepage. Also note any weld repairs or repair plates on the neck or draft arms.

5. Cutting Edge: Closely inspect cutting edge, pan, and bowl for damage, any missing bolts, and general appearance.

6. Chain: Inspect the chain carefully for any broken links, missing pins, or damaged sections. Make sure the elevator rollers turn freely. Inspect the bowl lift cylinders for any leaks, and check for any damage and overall condition. Also inspect the flights for any damage and if regrousing is necessary. Check for any cracks in factory welds, missing bolts from mounting brackets, and check all chain brackets for any damage and overall condition.

7. Speed Reducer: Inspect speed reducer for hydraulic leaks, damage, and overall condition. Carefully check factory welds for cracks on both sides of the scraper.

8. Tires: Inspect all tires for tread depth, and note any cracks, damage, or dry rot especially on sidewalls. Inspect brake system appearance for leaks, and overall appearance of rotors, drums, pads, and linings.

9. Stinger Structure: Inspect the stinger structure extending out from the bowl, for excessive push, pull, and any damage. Carefully inspect all factory welds in this area for cracks, breaks, and signs of overstressing.

ELEVATED SCRAPER

( See INSPECTION DIAGRAM Below )

BARDSTOWN, KENTUCKY